In the previous “Road to the M9” article, we mentioned the US Navy’s Vietnam-era adoption of the S&W Model 39 and its specialty suppressed variant for the SEAL teams, the Mk 22 Mod 0. Post-Vietnam, the SEALs supplemented the Mk 22 pistol with the use of revolvers for Over the Beach (OTB) operations. First was the stainless steel S&W Model 66 .357 Magnum followed by the more rugged S&W Model 686 upon the latter’s commercial introduction.

Even while the original USAF and JSSAP testing was still ongoing, SEAL Teams 2 and 6 were early adopters of the Beretta 92S. KAC made an early reputation for itself by refurbishing legacy SEAL weapons such as the Stoner 63 and the Mk 3 “Hush Puppy” suppressors. With the move towards Beretta by the SEALs, KAC produced conversions of Beretta 92S to utilize the legacy Mk 3 “Hush Puppy” suppressor. The conversions featured shortened slides, high profile adjustable sights, and a frame-mounted slide-lock.

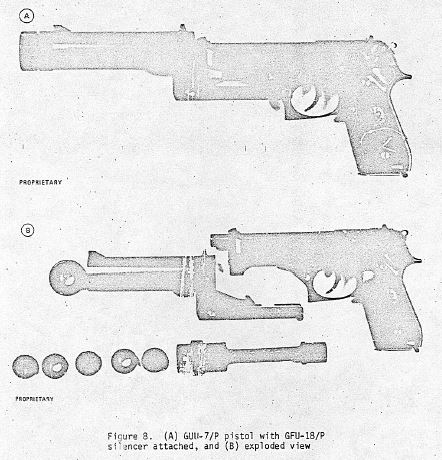

When the original XM9 requirements had the suppressor-friendly requirements stripped out, the US Air Force (USAF) and Navy continued their research on behalf of JSSAP. In 1983, Smith & Wesson and Beretta each received a small award from the USAF for dedicated silenced 9x19mm pistols. These were respectively known as the GUU-6/P and GUU-7/P. In May 1985, Air Force began testing at Eglin Air Force Base in Florida. The S&W Mk 22 Mod 0 was used as a control, and additional unsolicited proposals came from Knight’s Armament and Qual-A-Tech. The USAF ultimately selected the KAC XM9 “Snap-On” suppressor conversion.

Circa 1986, the SEALs selected the HK P9S-N for OTB operations. These featured a screw-on stainless steel suppressor designed by Mickey Finn of Qual-A-Tech, which was licensed to HK for production. The same suppressor could be screwed onto the barrels of the HK MP5-N, MP5K-N, and later, the MP5K-PDW.

US Navy SEALs adoption of the SIG-Sauer P226

The Navy had actually experienced three breakages with the Beretta 92S, 92SB, and M9 before the Army took formal notice. The first was in early 1984, another on 23 September 1987, and the third on 7 January 1988.

The Navy reacted to the Army’s safety messages by issuing its own slide failure engineering bulletins. On 1 March 1988, the Navy issued an Engineering Bulletin limiting the use of the M9 pistol to operational and emergency use only, and that the weapon should not be used for training or familiarization purposes. On 7 March 1988, the Navy revised the Engineering Bulletin instituting replacement of slides after 3,000 rounds fired in accordance with the Army Safety of Use Message. On 22 March 1988, the Navy lifted its restriction on the use of M9 for familiarization and training. However, on 19 April 1988, the Navy notified the Army that it would not accept delivery of any additional M9 until the slide failure problem had been resolved.

The same month, the Naval Special Warfare Command initiated a letter of operational requirements for an improved 9mm pistol. This requirement had the objective to accommodate their more extensive training firings, a longer required weapons service life, and the unique backup weapon role which requires reliable functioning in life-threatening situations. In July 1988, the Commander in Chief, US Atlantic Fleet forwarded an Inspector General Command inspection finding which recommended that if fixing the identified problems with the M9 pistol was not possible, a new weapon should be considered for NSW. In October 1988, the NSW requested 800 P226 for testing. A formal contract was issued in March 1989, and in June, the Navy approved a requirement for an improved 9mm handgun to replace the “interim” P226.

Offensive Handgun Weapons System

Meanwhile, on 16 April 1987, the US Special Operations Command (USSOCOM) was established. The first commander of SOCOM was General James J. Lindsey (US Army). One of his first orders assigned Major Gus Taylor (US Army) to conduct a study of all of the types of small arms that were in SOCOM’s inventory. Maj. Taylor found that there were 120 different types/configurations of small arms in use. Gen. Lindsay was very concerned by these findings, given the logistical burden in spare parts for maintenance. Gen. Lindsay followed up with an order to Maj, Taylor to produce a plan to develop standardized weapons that could be used by all of SOCOM’s various units.

In October 1989, SOCOM began to draw up a requirement for an Offensive Handgun Weapons System (OHWS). The standard service personal defense weapons, the M9 and SIG-Sauer P226 were considered inadequate for offensive combat due to their 9x19mm chambering. While the M1911A1 was chambered for the more than adequate .45 Auto, the weapon itself was not considered to be sufficiently reliable without significant customizing and vigilant maintenance. Moreover, none of the standard weapons in inventory were factory equipped for use with suppressors or lights/lasers. In December 1989, the OHWS program office was established at Naval Weapons Support Center – Crane (NWSC-Crane). Chuck Zeller was chosen as the Program Manager.

The 97 page Joint Service Operational Requirement (JSOR) was officially issued in February 1990. Boiled down to the essentials, the bidders would have to supply a semi-auto pistol, magazines, sound suppressor, laser aiming module, and enhanced .45 Auto ammunition. The program would be a three phase effort supervised by NWSC-Crane. However, the manufacturers quickly found that none of the ammunition companies were then interested in developing an enhanced .45 ACP cartridge, as the liability risks would be too great that the ammunition could find its way into older weapons of dubious strength/quality. On 1 February 1991, NWSC-Crane backed off of this requirement, stating that commercial .45 Auto +P ammunition would suffice.

Basic requirements included::

1) Chambered for .45 M1911 Ball;

2) Maximum Weight – Unequipped/unloaded -2.86 lbs and Fully Equipped/loaded – 5.5 lbs;

3) Maximum Length – Pistol 9.4 inches / System 15.75″;

4) Maximum Height – 5.9″;

5) Maximum Width – 1.4″;

6) Frame-mounted decocker;

7) Manual safety;

8) Passive firing pin safety;

9) Traditional double action;

10) Slide stop for last round hold-open;

11) Slide lock for single-shot use;

12) Interchangeable magazine release for right/left-hand users;

13) Beveled magazine well;

14) Interchangeable parts without fitting or special tools;

15) Toolless field stripping;

16) Corrosion resistant/non-reflective finish;

17) No aluminum or zinc parts;

18) Lanyard loop;

19) Non-slip grip tolerant of rough treatment, temperature extremes, and lubricants/solvents;

20) Gloved finger friendly trigger guard;

21) System capable of submersion to 66 feet of saltwater for 130 minutes;

22) No magazine disconnect;

23) Integral recoil compensator;

24) Suppressor sound reduction of 30 decibels;

25) Minimum 10 round magazine capacity with toolless user disassembly possible within 40 seconds;

26) Drop-free, interchangeable magazines;

27) Replaceable fixed iron sights;

28) Laser Aiming Module powered by two AA batteries capable of visible and infrared lasers with visible white light;

29) LAM capable of toolless mounting within 15 seconds; and

30) Minimum rounds before parts replacement – 30,000 / Minimum service life of slide and frame – 60,000 rounds.

On 27 November 1990, a pre-solicitation industry conference for the OHWS was held. Representatives from Arms Tech Ltd., Beretta, Colt, Glock, Heckler & Koch, Innovative Defense Solutions, Insight Technologies, Israeli Military Industries, Knight’s Armament Company, L&L Industries, Olin/Winchester, Ruger, S-Tron, Saco Defense, SIGarms, Smith & Wesson, Trijicon, and True Position Engineering were in attendance. The formal Request for Proposals (RFP) was issued in December 1990.

Colt and Heckler & Koch were each awarded $1.4 million developmental contracts on 28 August 1991 with the expectation that each would deliver 30 prototype OHWS within a year. HK’s Helmut Weldle managed to rework his efforts from the USP project already in progress to meet the SOCOM requirements. Colt, on the other hand, combined two of its least successful designs, using the frame/trigger mechanism of the Double Eagle and the rotating barrel design of the All-American 2000. HK easily made the delivery date, but Colt didn’t deliver until 27 October 1992.

By the end of the Phase I testing, 30,000 rounds of +P ammunition plus another 6,000 proof rounds had been fired through each manufacturer’s submissions. Certain preferences became clear: the HK handgun was the clear favorite; the Knight Armament Company “snap-on” suppressor of the Colt entry easily trounced the HK in-house suppressor design; and while the Insight Technologies LAM of the HK pistol needed work, it was better than the S-Tron LAM used by the Colt. Colt was eliminated from the competition, leaving only HK for Phase II.

On 3 January 1994, HK received another $1.39 million for an additional 30 OHWS prototypes, equipped this time with a KAC suppressor designed by Doug Olsen. There were some growing pains adapting a Nielsen Device to the KAC to work with the HK pistol, but the issues were overcome. The new prototype pistols and suppressors were delivered 28 November 1994. These prototypes easily sailed through another 30,000 rounds of testing at Bill Rogers’ shooting school, leading to the production contract award of Phase III on 28 June 1995. The initial $4.5 million order was for 1,950 pistols and 10,140 magazines. The HK OHWS was ultimately designated the Mk 23 Mod 0.

Olin/Winchester developed two +P rounds for the Mk 23: a 230gr Ranger Talon variant (DODIC A47X) and a 185gr FMJ-TC load (DODIC AA18). Triton Cartridge is also known to have supplied an unknown quantity of .45 Super ammunition using a 185gr FMJ-TC.

You’re not a Navy SEAL until you’ve tasted Italian steel!

LikeLike

All of those pistols fell out of the ugly tree and hit every branch on the way down.

LikeLike