By Kevin O’Brien

In a post we wrote a couple of years ago but that never appeared on this blog (because it was never finished), we wrote about legendary 20th Century riflesmith and cartridge wildcatter Parker Otto Ackley, known to all as P.O. Ackley.

PO Ackley made an entire career of making what he called “improved” cartridges. Each of the Ackley improved cartridges was based on some mainstream cartridge but with an increased powder capacity and a sharper shoulder, which implies less taper in the body of the cartridge itself.

We described Ackley similarly in another post that did get published, in 2012. That of course understates Ackley’s career, because apart from all his cartridge wizardry, Ackley was a gunsmith, barrel maker, and a writer with a prodigious capacity for work.

in a new book by Fred Zeglin, this career is explored and evaluated, and Zeglin actually emulates some of Ackley’s famous experiments, including these on Bolt Thrust that are excerpted at GunDigest.com.

Since the post-WWII years, if not before, there has been an ongoing argument concerning whether breech thrust (bolt thrust) is reduced by the improved case design. P.O. Ackley has certainly influenced the argument. The definition of an improved case is pretty simple. The case body is blown out to minimum body taper, which is described by Ackley as 0.0075 per inch taper. Shoulder angles between 28 and 45 degrees are normally considered to be improved, although it could be argued that any shoulder sharper than the original parent case is improved. Finally, an improved design allows the firing of a factory cartridge in order to fireform the brass for the new design.

…a method of recording breech trust was necessary in order to go beyond the somewhat subjective experiments that P.O. Ackley wrote about in Handbook for Shooters and Reloaders Vol. I. There Ackley used a Model 94 Winchester because, as he stated, “We often hear that the Winchester Model 1894 action was designed for low pressures and is an action which could be described as ‘weak.’” The purpose of his experiment with the ‘94 was to prove that the improved case design minimized bolt thrust; that the brass will support and contain some pressure; that oily chambers increase bolt thrust; and finally, the notion that actions are designed for specific pressure ranges is a fallacy.

Zeglin conducted a high-tech version of Ackley’s tests, using a test fixture he developed, “a .30 caliber barrel with a universal breech plug to allow for adjustable headspace, and to accommodate the strain gauge utilized by the Pressure Trace.” He developed loads beyond the SAAMI pressure limit for the .30-30 Improved, and discovered that even with excess headspace, the Improved case stayed in place, extruding the primer instead of shearing its head off. Conclusions:

[W]as Ackley right about his findings?

Yes, but he may have missed a point or two.Since .30-30 brass is thick and pressures are low relative to brass strength and case capacity, with most appropriate powders pressure is not a big problem. To be fair, we did find some powders that will develop pressure far beyond SAAMI levels for the .30-30 AI case. Because the brass is so thick, it actually cannot stretch and cause head separations due to excess headspace. In that respect the .30-30 is not a good choice for Ackley to prove that improved designs handle pressure better.

However, Ackley used the .30-30 because the ‘94 Winchester action had been labeled weak. In this respect, Ackley did prove that the ‘94 can handle anything the .30-30 or .30-30 AI can dish out, without any question.

Bear in mind that the action of the Winchester ’94 was labeled weak by Winchester, who wanted to upsell customers to stronger rifles, like the ’95, which could handle the big-game and service cartridges of the early 20th Century with no problems.

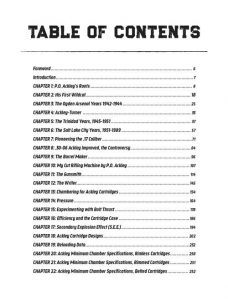

There’s quite bit more to it, so Read The Whole Thing™. In other things in the book there is something that made us order it: Ackley’s own, previously unpublished, description of his own home-made cut rifling machine. (See the Table of Contents left).

Like any highly specialized book, it’s expensive, and has potential to go out of print at some time in the future. That’s just life in specialty book markets.

How expensive? The list price for hardcover or eBook is $60, although at this writing Gun Digest is sweetening the deal with $10 off the hardcover edition, and free shipping. (Pity they don’t offer a deal on both. We prefer hardcover books, but you can take a Kindle or iPad into the shop without worrying about getting cutting fluid on an irreplaceable heirloom). For what it’s worth, we just ordered the hardcover.

While this book rates the full price (to us at least), Gun Digest publishing does find itself overstocked from time to time, and if you’re into gun books and willing to let price be your guide, they have Under $30 and Under $15 pages, too. Free shipping if you can run the tab to $50 — we bet you can. (Dunno what the shipping is to those of you dwelling in foreign lands).

I have three of Fred’s books. If you’re serious about gunsmithing, the reamer/cutting tool, chambering books are very good. The wildcat/Ackley books are more applicable to those who want to build a wildcat.

LikeLike